We are A.N.I Enterprises Our Quality Policy.

All our products are manufactured according to ASTM standards and tested regularly prior to each deliveryin our own laboratory which is fully equipped with modern testing facilities and by professional laboratory technicians. Also our products tested and certified by Bitumen laboratory of Road Development Authority of Sri Lanka on a regular basis in order to ensure the credibility.

The organization’s entire process is certified under ISO 9001:2015 standard. We are equipped with 04 Modern Decanting Plants which can produce approximately 3.5Million Liters of Hot Bitumen per Month, MC.30 plant with the capacity of 400,000 litres of Bitumen cutback and emulsion production unit which can produce 1.2Million litres of bitumen emulsion per Month.

1. We are committed to provide Quality Products and Services to ensure it is delivered Within Budget, On Time and provide Value-for-Money.

2.Maintaining an effective quality management system.

3.cultivating an environmentally friendly culture.

4.Adopting progressive procurement strategy

OPTIMISING BITUMEN PERFORMANCE

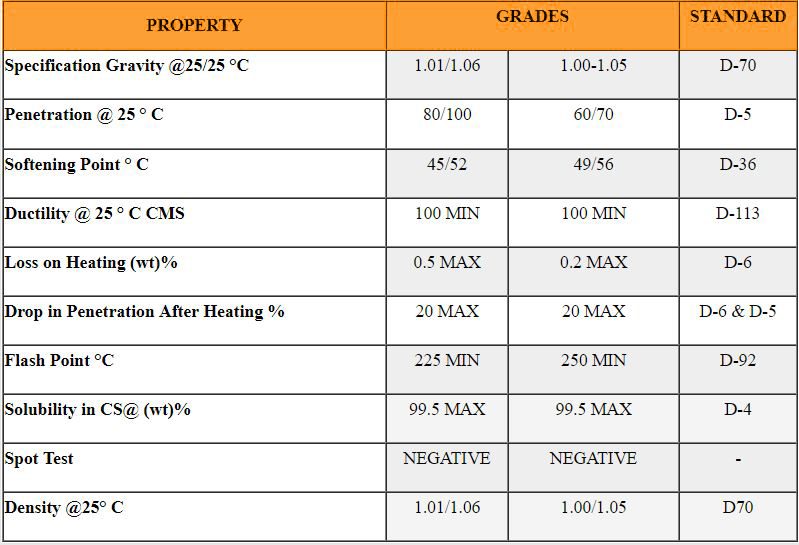

SPECIFICATION OF PENETRATION GRADE BITUMEN

Cutback Bitumen’s we supply MC-30 & MC-70

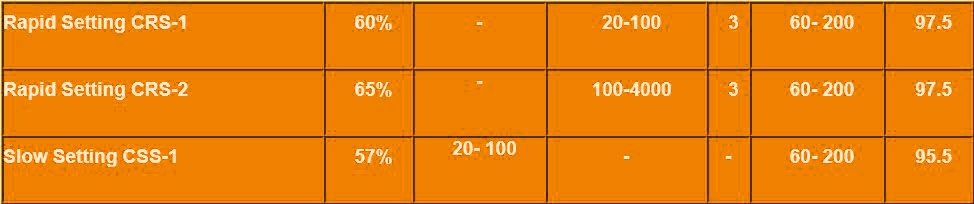

Bitumen Emulsions we supply cationic Slow Setting and cationic Rapid setting Emulsions.

Bitumen Emulsion CSS-1,CRS-1 & CRS-2.

Advantages of Bitumen emulsions

a) Cationic emulsions may be used at ambient temperatures with aggregates, which need not be completely dry.

b) Lower costs are incurred due to a considerable saving on fuel for heating purposes.

c) Operating at lower temperatures for cold mixing gives a greater margin of safety, even though these emulsions may contain fluxing oil.

d) Not only may cold mix be stockpiled for long periods, but it may also be packaged in small containers and stored. This facilitates the treatment of very small areas quickly, cleanly and economically.

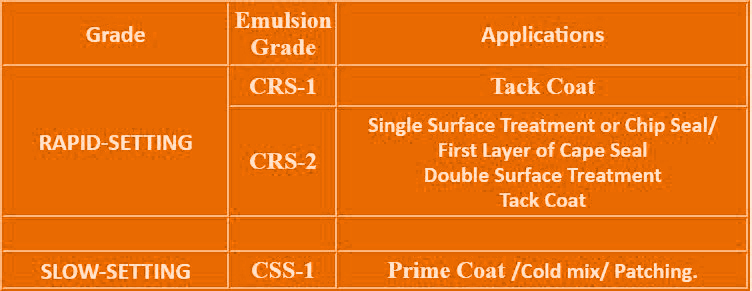

EMULSION APPLICATIONS

SPECIFICATION